Types of Weighbridge Installation

Weighbridges, also known as truck scales, are critical for measuring the weight of vehicles and their loads. Depending on the site conditions, operational requirements, and budget, weighbridges can be installed in various configurations. Below are the main types of weighbridge installations:

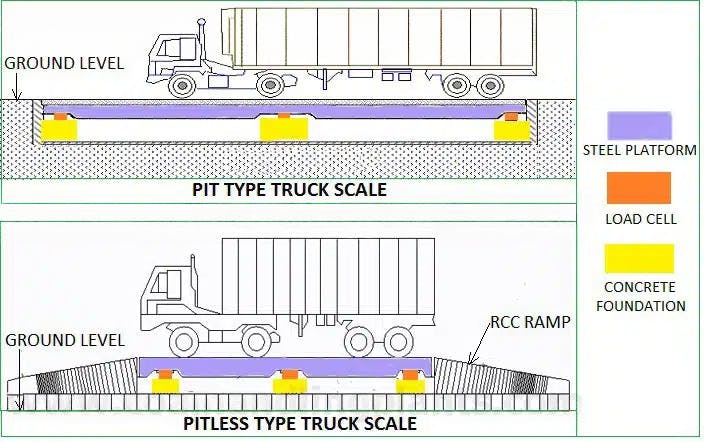

1. Pit Type Weighbridge

A pit type weighbridge is installed with the platform flush to the ground level. The entire structure sits inside a pit, which houses the load cells and other components. This installation is ideal for places with limited space, as vehicles can approach the scale from any direction. It’s commonly used in urban areas and factories where space optimization is important.

Testing

Advantages:

- Space-efficient

- Easier for vehicles to drive on and off from any direction

- No need for ramps

Disadvantages:

- Requires civil excavation and drainage

- Higher maintenance in water-logged areas

2. Pitless (Surface Mounted) Weighbridge

Pitless weighbridges are installed above ground level and require ramps on either side for vehicle access. This type is quicker and easier to install and is ideal for areas where pit excavation is difficult or costly.

Advantages:

- Lower civil work costs

- Easier maintenance and inspection

- Suitable for flood-prone areas

Disadvantages:

- Requires more space for ramps

- Vehicles can approach only from specific directions

3. Portable Weighbridge

Portable or modular weighbridges are designed for quick installation and dismantling. These are used in temporary locations such as construction sites, mining areas, or remote operations where permanent installations are not feasible.

Advantages:

- Fast installation and relocation

- Minimal civil work required

- Cost-effective for short-term use

Disadvantages:

- May not be suitable for very high traffic or heavy loads

- Less durable than fixed options

4. Mobile Weighbridge

A mobile weighbridge is mounted on a vehicle or trailer and can be driven to different locations. This is particularly useful for logistics companies, road transport authorities, or industries where weight checks are needed at various sites.

Advantages:

- Maximum flexibility

- No fixed installation required

- Ideal for field operations

Disadvantages:

- Limited capacity compared to stationary systems

- Requires trained operators

5. Rail Weighbridge

Designed to weigh railway wagons, rail weighbridges can be either static or dynamic (in-motion). These are critical in industries where bulk materials are transported by rail, such as coal, cement, and steel.

Advantages:

- Suitable for large-scale logistics

- Accurate weighing for rail freight billing

Disadvantages:

- Requires integration with railway infrastructure

- High initial cost

6. In-Motion Weighbridge

In-motion weighbridges allow vehicles or railcars to be weighed without stopping. These systems use advanced sensors and software to capture accurate weight readings as the vehicle moves across the platform.

Advantages:

- Saves time and increases efficiency

- Ideal for high-traffic areas

Disadvantages:

- More complex and expensive

- Slightly lower accuracy than static systems